Khoom

-

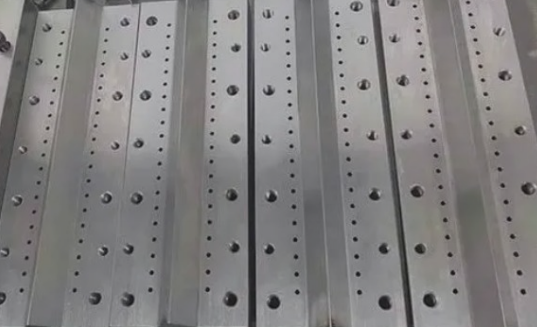

Muaj Extruction Mould

Peb Muaj Extruction Moulds, tsim los ntawm Kaihua Mould, khav theeb lub teeb yuag thiab kev ua haujlwm zoo, ua rau lawv zoo tagnrho rau kev ua ntau yam ntaub ntawv xws li yeeb nkab, bar, monofilament, ntawv, zaj duab xis, hlau thiab cable coatings, thiab cov ntaub ntawv tshwj xeeb zoo li.Siv cov ntaub ntawv qib siab tshaj plaws nrog rau cov cuab yeej tuag zoo tshaj plaws, thiab cov neeg ua haujlwm los ntawm cov kws tshaj lij hauv metallurgy, kev kho cua sov, thiab txheej txheej, Kaihua Mould tau cog lus los muab qhov zoo tshaj plaws thiab qhov tseeb.Txawm hais tias koj tab tom nrhiav los txhim kho koj cov txheej txheem tsim khoom lossis txhim kho koj cov khoom lag luam, peb cov Extruction Dies yog qhov kev xaiv txhim khu kev qha. -

Soundproof Granulators

Kaihua Mould zoo siab los muab peb Cov Ntawv Pov Thawj Zoo Tshaj Plaws, tsim tshwj xeeb rau kev rov ua dua tshiab ntawm cov khib nyiab thiab cov khoom tsis lees paub los ntawm kev txhaj tshuaj molding, tshuab moulding, lossis cov kab extrusion.Peb cov cav tov muaj cov qauv zoo uas ua kom muaj kev ua haujlwm yooj yim thiab hloov cov hniav sai, ua rau rov ua dua tshiab.Cov suab pov thawj granulators no yog qhov kev xaiv zoo tshaj plaws rau cov tuam txhab nrhiav kom txo lawv cov pa roj carbon hneev taw thaum txhim kho lawv cov kab hauv qab.Thiab nrog rau Kaihua Mold txoj kev cog lus los muab cov kev daws teeb meem zoo uas ua tau raws li cov qauv kev lag luam uas xav tau tshaj plaws, koj tuaj yeem tso siab tau tias koj tau nqis peev zoo rau koj txoj kev lag luam.Hu rau peb hnub no kom paub ntau ntxiv txog peb Cov Ntawv Pov Thawj Zoo Tshaj Plaws. -

Headlight Cover Pwm-Ob Xim Pwm

Peb ntawm Kaihua Pwm tshwj xeeb hauv kev tsim cov yas txhaj tshuaj zoo rau lub taub hau npog Pwm-ob xim Pwm.Peb yog ib qho chaw nres tsheb rau tag nrho koj lub tsheb teeb yas sib dhos xav tau.Peb pab neeg ntawm cov kws tshaj lij ua kom ntseeg tau tias peb xa cov kev daws teeb meem zoo rau peb cov neeg siv khoom.Peb zoo siab heev los muab peb cov neeg siv khoom nrog cov khoom zoo tshaj plaws uas muaj kev ruaj khov thiab txhim khu kev qha.Peb cov thev naus laus zis thev naus laus zis thiab cov neeg ua haujlwm txawj ua haujlwm tso cai rau peb xa cov khoom lag luam siab tshaj plaws uas ua tau raws li cov lus qhia meej ntawm peb cov neeg siv khoom, ua rau peb yog ib qho ntawm cov neeg siv khoom lag luam zoo tshaj plaws hauv kev lag luam. -

Tuag Casting Pwm

Kaihua Mould yog cov chaw tsim khoom ntawm Tuag Casting Mould.Peb lub hom phiaj yog los muab cov pwm tsim tau zoo thiab ua tau zoo kom tsis txhob muaj kev ua haujlwm thib ob.Peb ib txwm muab qhov tseem ceeb rau thawj txoj kev tsim, uas ua kom muaj txiaj ntsig zoo, txo cov nqi siv hluav taws xob, cov khoom siv ntau lawm, thiab hnav tsawg dua.Peb cov kws tshaj lij hauv automotive pwm tsis yog qhov thib ob.Nrog peb cov cuab yeej tsim khoom siab heev thiab kev tswj hwm nruj, peb lav kom xa tsuas yog qhov zoo tshaj plaws tuag casting pwm rau koj cov kev xav tau ntawm kev tsim tsheb.Ntawm Kaihua Mould, precision thiab zoo yog peb qhov tseem ceeb tshaj plaws. -

Yas Tshuab Moulding cuab yeej

Peb tshwj xeeb hauv kev tsim cov khoom siv sab saum toj-ntawm-tus-kab Yas Tshuab Moulding uas ua tau zoo hauv kev zoo nkauj thiab kev ua haujlwm zoo.Peb Kaihua pwm tsim yog lub tswv yim tshiab, muab cov kev daws teeb meem zoo zog uas ua kom yooj yim cov duab tsim thiab txhim kho cov nqi tsim khoom.Nrog peb cov kws tshaj lij, peb xyuas kom meej tias peb cov neeg tau txais tsuas yog cov cuab yeej zoo tshaj plaws tshuab moulding uas haum rau lawv cov kev xav tau tshwj xeeb.Xaiv Kaihua rau tus khub uas ntseeg siab hauv kev tsim cov cuab yeej saum toj kawg nkaus uas ua tau raws li koj cov hom phiaj tsim khoom thiab tshaj qhov koj xav tau.Muaj kev paub zoo tshaj plaws hauv tshuab tshuab moulding nrog peb cov kev pabcuam kws tshaj lij. -

Hlau 2358

Hlau 2358 yog cov khoom siv ntau yam wrought alloy steel uas tau dhau los ua kev xaiv nrov hauv kev tsim khoom.Nws cov khoom siv zoo heev thiab hnav tsis kam ua rau nws hloov tau zoo rau 7CrSiMnMoV.Ib lub tuam txhab paub zoo, Kaihua Mould, tau lees paub lub peev xwm ntawm Steel 2358 thiab muab tso rau hauv lawv cov txheej txheem tsim khoom.Kev siv cov khoom siv tshiab no tau ua kom zoo dua qub thiab qhov tseeb ntawm lawv cov pwm, ua rau cov khoom zoo dua qub.Steel 2358 yog ib qho tseem ceeb hauv lub ntiaj teb kev tsim khoom niaj hnub, thiab nws cov koob meej tsuas yog tsim kom loj hlob yav tom ntej. -

cev 2767

Hlau 2767 los ntawm Kaihua Mould yog qhov kawg daws rau cov khoom hnyav hnyav hnyav stamping tuag, txhaj tshuaj tuag, thiab cov cuab yeej txiav hnyav.Cov qib steel no paub txog nws qhov tshwj xeeb hardness, lub zog, thiab kav ntev, ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov ntawv thov uas yuav tsum tau hnav thiab tsim kua muag.Nws cov khoom tshwj xeeb ua rau nws yog qhov kev xaiv zoo tshaj plaws rau kev siv hauv kev lag luam, vim nws tuaj yeem tiv taus cov khoom hnyav thiab muaj kev cuam tshuam loj.Kev sib xyaw ua ke ntawm cov tawv thiab tawv ua rau Steel 2767 qhov kev xaiv ntawm cov kws tshaj lij uas xav tau cov qauv zoo tshaj plaws.Yog li yog tias koj tab tom nrhiav rau qib steel txhim khu kev qha thiab ruaj khov, koj tuaj yeem ua tsis ncaj ncees nrog Steel 2767 los ntawm Kaihua Mould. -

Hlau 3Cr13/4Cr13

Hlau 3Cr13 / 4Cr13, tsim los ntawm Kaihua Mould, yog cov khoom siv txhim khu kev qha thiab ntau yam rau kev tsim cov khoom siv siab, cov cuab yeej, thiab cov khoom siv.Hom martensitic stainless hlau no paub txog nws zoo heev corrosion kuj, zoo machinability, siab zog, hnav tsis kam thiab muaj peev xwm los tuav lub siab polishing.Rau cov laj thawj no, nws feem ntau siv hauv kev lag luam xws li aerospace, tsheb, kev kho mob, thiab kev ua zaub mov.Nrog Kaihua Mould qhov kev txawj ntse hauv kev tsim cov hlau, cov neeg siv khoom tuaj yeem tso siab rau qhov zoo ntawm Steel 3Cr13/4Cr13 los tsim cov khoom ruaj khov thiab kav ntev. -

Hlau 5CrNiMo/5CrNiMoV

Hlau 5CrNiMo / 5CrNiMoV yog ib qho kev ua haujlwm kub kub tuag hlau uas paub txog nws qhov zoo heev toughness, lub zog, hnav tsis kam, thiab hardenability.Hom hlau no feem ntau yog siv los tsim cov pwm loj thiab nyuaj, xws li cov khoom tsim los ntawm Kaihua Mould.Qhov no yog vim cov hlau muaj peev xwm zoo heev los tswj nws cov duab, txawm tias thaum raug kub thiab siab.

Ntxiv rau nws cov ntsiab lus siab alloy, Steel 5CrNiMo / 5CrNiMoV kuj tseem muaj cov pa roj carbon ntau thiab chromium.Cov ntsiab lus no ua hauj lwm ua ke los txhim kho cov hlau tag nrho lub zog thiab hardness, muab ib qho zoo tagnrho ua ke ntawm toughness thiab durability.Tsis tas li ntawd, hom hlau no paub txog nws lub peev xwm los tiv thaiv kev tawg thiab deformation, txawm tias thaum muaj kev ntxhov siab ntau.

Zuag qhia tag nrho, Steel 5CrNiMo / 5CrNiMoV yog qhov kev xaiv zoo tshaj plaws rau kev siv hauv kev tsim cov khoom zoo, cov qauv pwm.Nws qib siab ntawm toughness, lub zog, hnav tsis kam, thiab hardenability ua rau nws yog ib qho khoom siv zoo tshaj plaws rau kev siv ntau yam, los ntawm cov khoom siv tsheb mus rau cov khoom siv tshuab precision thiab tshaj.Txawm hais tias koj yog cov chaw tsim khoom, tus tsim qauv, lossis tus kws tshaj lij, koj tuaj yeem tso siab rau Steel 5CrNiMo / 5CrNiMoV los muab kev ua haujlwm thiab ua haujlwm ntev uas koj xav tau.. -

Hlau 40Cr

Steel 40Cr yog ib tug nruab nrab carbon siab zog carbon structural steel.Nws lub zog siab thiab hardness ua rau nws muaj kev xaiv nrov hauv ntau qhov kev lag luam, suav nrog kev tsim cov pwm ua haujlwm siab.

Ib lub tuam txhab uas siv Steel 40Cr hauv nws cov txheej txheem pwm yog Kaihua Mould.Nrog rau ntau tshaj 20 xyoo ntawm kev paub hauv pwm tsim thiab tsim, Kaihua Mould tau mob siab rau siv cov ntaub ntawv zoo tshaj plaws thiab thev naus laus zis los tsim cov pwm zoo rau lawv cov neeg siv khoom.

Steel 40Cr yog ib qho zoo meej haum rau Kaihua Mould cov kev xav tau, vim nws tuaj yeem kho tau yooj yim thaum tshav kub kub kom ua tiav qhov xav tau ntawm hardness thiab lub zog.Txawm hais tias nws yog normalizing, quenching thiab tempering, los yog high-frequency nto quenching, Steel 40Cr tuaj yeem raug kho kom tau raws li cov kev cai tshwj xeeb ntawm cov pwm pwm.

Kaihua Mould kev cog lus rau kev siv cov khoom zoo li Steel 40Cr tsuas yog ib txoj hauv kev uas lawv ua kom lawv cov pwm zoo tshaj plaws.Los ntawm kev sib txuas lawv cov kev txawj ntse nrog cov thev naus laus zis tshiab thiab cov ntaub ntawv, Kaihua Mould tseem ua tus thawj coj hauv kev lag luam pwm. -

Hlau P20H

Steel P20H yog ib tug pre-hardened forged yas pwm steel uas muaj tshwj xeeb machinability, weldability, thiab seem stability.Tsis zoo li cov pa pwm hlau, Steel P20H tuaj yeem xa tuaj rau hauv lub xeev pre-hardened, tshem tawm qhov xav tau kev kho cua sov.Yog li ntawd, cov tuam ntxhab tuaj yeem txo lub sijhawm tsim kho kom zoo, txo cov nqi tsim khoom, thiab txhim kho kev ua haujlwm tag nrho.

Ntawm Kaihua Mould, peb nkag siab qhov tseem ceeb ntawm kev siv cov ntaub ntawv saum toj kawg nkaus hauv cov txheej txheem pwm.Yog vim li cas peb thiaj li pom zoo rau Steel P20H vim nws muaj kev ruaj khov zoo heev thiab tsis kam hnav thiab tsim kua muag.Peb pab pawg kws tshaj lij muaj kev paub dav dav ntawm cov cuab yeej tshiab thiab cov txheej txheem hauv kev tsim pwm, uas ua kom peb tuaj yeem xa cov khoom tiav thiab cov khoom zoo.

Hlau P20H kuj zoo tagnrho rau kev txhaj tshuaj molding, extrusion, thiab tshuab moulding txheej txheem vim nws cov khoom muaj zog, toughness, thiab zoo machinability.Cov khoom siv ntau yam no tau siv dav hauv kev lag luam tsheb, hluav taws xob, thiab cov neeg siv khoom lag luam.Steel P20H los ntawm Kaihua Mould yog qhov kev xaiv zoo heev. -

Hlau C45 / CK53

Steel C45 / CK53 yog ib tug nruab nrab carbon siab zog carbon structural steel nrog zoo heev mechanical zog.Nws yog dav siv nyob rau hauv ntau yam kev siv, xws li machinery manufacturing, cuab yeej, thiab tsheb qhov chaw.Kaihua Mould, tus thawj coj steel xa khoom, muab Steel C45 / CK53 hauv ntau qhov ntau thiab tsawg thiab cov ntaub ntawv kom tau raws li cov neeg siv khoom sib txawv.Lawv muab cov hlau zoo tshaj plaws uas dhau los ua cov txheej txheem tswj xyuas kom zoo los xyuas kom meej nws lub zog thiab kav ntev.Tom qab quenching, Steel C45 / CK53 muaj zog thiab hardness, ua rau nws haum rau siv nyob rau hauv hnyav ib puag ncig.Nws feem ntau yog siv tom qab kev kho cua sov xws li normalizing los yog quenching thiab tempering, los yog high-frequency nto quenching.Hauv cov ntsiab lus, Steel C45 / CK53 yog qhov kev xaiv zoo tshaj plaws rau cov ntawv thov uas xav tau lub zog siab thiab ua haujlwm ntev.Kaihua Mould muaj cov hlau zoo uas ua tau raws li lawv cov neeg siv khoom xav tau, ua kom ntseeg tau thiab ua haujlwm tau zoo..