Raw Khoom

-

Xim Masterbatch

Xim masterbatch yog ib yam tshiab ntawm cov xim tshwj xeeb rau cov khoom siv polymer, siv rau hauv cov yas, sib tov me me ntawm cov xim masterbatch thiab cov xim tsis muaj xim thaum ua tiav tuaj yeem ua tiav cov xim xim lossis cov khoom lag luam nrog cov xim xim tsim. -

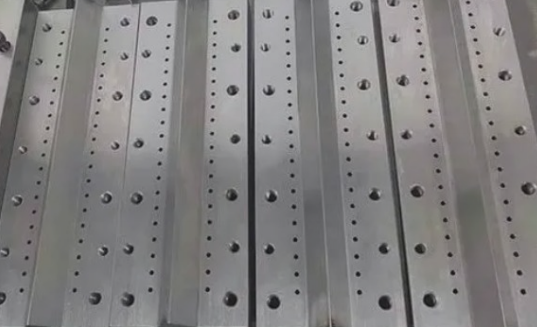

Hlau 2344

Peb Cov Phab Ntsa Mounted Combined Pegboard Sawv Teeb yog qhov zoo ntxiv rau txhua qhov chaw ua haujlwm.Ua los ntawm cov hlau zoo 2344 thiab precision machined los ntawm Kaihua Mould, nws yog ob qho tib si ruaj thiab ua haujlwm.Nrog nws cov kev xaiv pegboard sib txawv, koj tuaj yeem hloov kho koj lub koom haum yooj yim kom haum rau koj cov kev xav tau tshwj xeeb.Lub phab ntsa-mounted tsim ua kom koj qhov chaw zoo tshaj plaws thiab ua kom koj thaj chaw ua haujlwm huv si thiab ua haujlwm zoo.Txawm hais tias koj yog tus nyiam DIY lossis tus kws tshaj lij hauv kev xav tau ntawm qee lub koom haum, Pegboard Stand Set yog qhov kev xaiv zoo heev.Tau txais koj li niaj hnub no thiab hloov pauv txoj kev koj ua haujlwm. -

cev 2738

Steel 2738 yog ib qho uas feem ntau siv cov hlau rau kev tsim pwm vim nws cov khoom siv hluav taws xob zoo heev thiab cov khoom muaj zog.Ntawm cov tuam txhab uas siv cov hlau no, Kaihua Mould yog cov chaw tsim khoom zoo thiab muaj npe nrov rau cov pwm zoo.Lawv cov kws tshaj lij hauv kev tsim pwm ua ke nrog kev ntseeg siab ntawm Steel 2738 muab cov pwm uas ruaj khov thiab ua haujlwm zoo hauv ntau yam lag luam xws li tsheb, aerospace, thiab ntim khoom.Xaiv Steel 2738 thiab Kaihua Pwm lav lub pwm zoo rau txhua yam khoom tsim khoom xav tau. -

Hlau C45 / CK53

Steel C45 / CK53 yog ib tug nruab nrab carbon siab zog carbon structural steel nrog zoo heev mechanical zog.Nws yog dav siv nyob rau hauv ntau yam kev siv, xws li machinery manufacturing, cuab yeej, thiab tsheb qhov chaw.Kaihua Mould, tus thawj coj steel xa khoom, muab Steel C45 / CK53 hauv ntau qhov ntau thiab tsawg thiab cov ntaub ntawv kom tau raws li cov neeg siv khoom sib txawv.Lawv muab cov hlau zoo tshaj plaws uas dhau los ua cov txheej txheem tswj xyuas kom zoo los xyuas kom meej nws lub zog thiab kav ntev.Tom qab quenching, Steel C45 / CK53 muaj zog thiab hardness, ua rau nws haum rau siv nyob rau hauv hnyav ib puag ncig.Nws feem ntau yog siv tom qab kev kho cua sov xws li normalizing los yog quenching thiab tempering, los yog high-frequency nto quenching.Hauv cov ntsiab lus, Steel C45 / CK53 yog qhov kev xaiv zoo tshaj plaws rau cov ntawv thov uas xav tau lub zog siab thiab ua haujlwm ntev.Kaihua Mould muaj cov hlau zoo uas ua tau raws li lawv cov neeg siv khoom xav tau, ua kom ntseeg tau thiab ua haujlwm tau zoo.. -

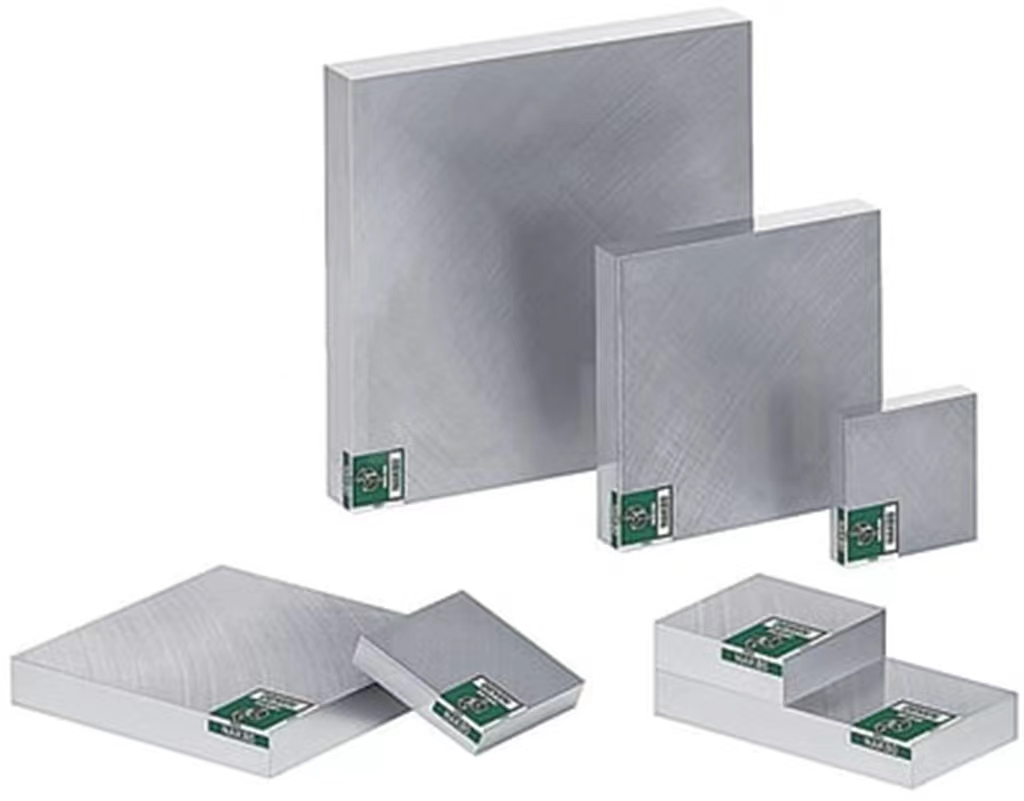

Steel NAK 80

Steel NAK80, ib tug pre-hard yas tuag steel, yog dav siv nyob rau hauv manufacturing kev lag luam vim nws cov khoom zoo heev.Kaihua Mould, tus thawj coj tuag casting pwm tsim, siv Steel NAK80 rau lawv cov kev daws teeb meem tshiab.Cov hlau no muaj cov yam ntxwv zoo kawg li xws li kev hnav tsis kam, plasticity, toughness, corrosion resistance, thiab superior polishing kev ua tau zoo.Nws sab saum toj paug machinability ua rau nws yooj yim rau siv nyob rau hauv tej daim ntawv thov kev lag luam.Kaihua Mould siv Steel NAK80 rau lawv cov pwm zoo uas ua kom muaj kev ruaj khov thiab ua tau zoo nyob rau hauv cov txheej txheem ntau lawm.Cia siab rau Kaihua Mould qhov kev txawj ntse hauv kev lag luam molding thiab kev ntseeg siab ntawm Steel NAK80 rau koj qhov project tom ntej. -

Hlau 718H / 2738H

Hlau 718H / 2738H yog cov khoom siv yas zoo tshaj plaws.Nws loj loj interface qauv, ua ke nrog tshwj xeeb hardness uniformity thiab toughness, muab unparalleled hnav tsis kam.Tsis tas li ntawd, nws nthuav tawm zoo heev corrosion kuj thiab abrasiveness, ua rau nws yog ib qho kev xaiv zoo tshaj plaws rau kev lag luam nyuaj.Ntawm Kaihua Mould, peb tshwj xeeb hauv kev tsim cov khoom siv ua haujlwm zoo siv Steel 718H / 2738H.Peb pab pawg kws tshaj lij tau cog lus rau cov qauv zoo thiab xa cov kev daws teeb meem ruaj khov, ua kom tau raws li peb cov neeg siv khoom xav tau.Cia siab rau peb los muab koj cov kev daws teeb meem zoo tshaj plaws steel rau koj cov kev xav tau kev lag luam. -

Hlau H13

Steel H13 yog qhov kev xaiv saum toj kawg nkaus rau cov hlau tuag vim nws cov khoom tshwj xeeb.Nws muaj cov thermal cuam tshuam zoo heev, siab tawv, thiab siab hardenability, ua rau nws siv ntau hom hlau tuag.Kaihua Mould ua kom cov khoom zoo tshaj plaws los ntawm kev siv Steel H13 hauv nws cov pwm, ua rau cov khoom lag luam zoo nrog tshwj xeeb toughness thiab plasticity.Lub purity thiab machinability ntawm Steel H13 ua rau nws yooj yim mus ua hauj lwm nrog, tso cai rau customized designs thiab seamless ntau lawm txheej txheem.Nws tsis yog qhov xav tsis thoob Steel H13 los ntawm Kaihua Mould yog qhov kev xaiv zoo tshaj plaws rau cov hlau tuag. -

Hlau 2358

Hlau 2358 yog cov khoom siv ntau yam wrought alloy steel uas tau dhau los ua kev xaiv nrov hauv kev tsim khoom.Nws cov khoom siv zoo heev thiab hnav tsis kam ua rau nws hloov tau zoo rau 7CrSiMnMoV.Ib lub tuam txhab paub zoo, Kaihua Mould, tau lees paub lub peev xwm ntawm Steel 2358 thiab muab tso rau hauv lawv cov txheej txheem tsim khoom.Kev siv cov khoom siv tshiab no tau ua kom zoo dua qub thiab qhov tseeb ntawm lawv cov pwm, ua rau cov khoom zoo dua qub.Steel 2358 yog ib qho tseem ceeb hauv lub ntiaj teb kev tsim khoom niaj hnub, thiab nws cov koob meej tsuas yog tsim kom loj hlob yav tom ntej. -

cev 2767

Hlau 2767 los ntawm Kaihua Mould yog qhov kawg daws rau cov khoom hnyav hnyav hnyav stamping tuag, txhaj tshuaj tuag, thiab cov cuab yeej txiav hnyav.Cov qib steel no paub txog nws qhov tshwj xeeb hardness, lub zog, thiab kav ntev, ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov ntawv thov uas yuav tsum tau hnav thiab tsim kua muag.Nws cov khoom tshwj xeeb ua rau nws yog qhov kev xaiv zoo tshaj plaws rau kev siv hauv kev lag luam, vim nws tuaj yeem tiv taus cov khoom hnyav thiab muaj kev cuam tshuam loj.Kev sib xyaw ua ke ntawm cov tawv thiab tawv ua rau Steel 2767 qhov kev xaiv ntawm cov kws tshaj lij uas xav tau cov qauv zoo tshaj plaws.Yog li yog tias koj tab tom nrhiav rau qib steel txhim khu kev qha thiab ruaj khov, koj tuaj yeem ua tsis ncaj ncees nrog Steel 2767 los ntawm Kaihua Mould. -

Hlau 3Cr13/4Cr13

Hlau 3Cr13 / 4Cr13, tsim los ntawm Kaihua Mould, yog cov khoom siv txhim khu kev qha thiab ntau yam rau kev tsim cov khoom siv siab, cov cuab yeej, thiab cov khoom siv.Hom martensitic stainless hlau no paub txog nws zoo heev corrosion kuj, zoo machinability, siab zog, hnav tsis kam thiab muaj peev xwm los tuav lub siab polishing.Rau cov laj thawj no, nws feem ntau siv hauv kev lag luam xws li aerospace, tsheb, kev kho mob, thiab kev ua zaub mov.Nrog Kaihua Mould qhov kev txawj ntse hauv kev tsim cov hlau, cov neeg siv khoom tuaj yeem tso siab rau qhov zoo ntawm Steel 3Cr13/4Cr13 los tsim cov khoom ruaj khov thiab kav ntev. -

Hlau 5CrNiMo/5CrNiMoV

Hlau 5CrNiMo / 5CrNiMoV yog ib qho kev ua haujlwm kub kub tuag hlau uas paub txog nws qhov zoo heev toughness, lub zog, hnav tsis kam, thiab hardenability.Hom hlau no feem ntau yog siv los tsim cov pwm loj thiab nyuaj, xws li cov khoom tsim los ntawm Kaihua Mould.Qhov no yog vim cov hlau muaj peev xwm zoo heev los tswj nws cov duab, txawm tias thaum raug kub thiab siab.

Ntxiv rau nws cov ntsiab lus siab alloy, Steel 5CrNiMo / 5CrNiMoV kuj tseem muaj cov pa roj carbon ntau thiab chromium.Cov ntsiab lus no ua hauj lwm ua ke los txhim kho cov hlau tag nrho lub zog thiab hardness, muab ib qho zoo tagnrho ua ke ntawm toughness thiab durability.Tsis tas li ntawd, hom hlau no paub txog nws lub peev xwm los tiv thaiv kev tawg thiab deformation, txawm tias thaum muaj kev ntxhov siab ntau.

Zuag qhia tag nrho, Steel 5CrNiMo / 5CrNiMoV yog qhov kev xaiv zoo tshaj plaws rau kev siv hauv kev tsim cov khoom zoo, cov qauv pwm.Nws qib siab ntawm toughness, lub zog, hnav tsis kam, thiab hardenability ua rau nws yog ib qho khoom siv zoo tshaj plaws rau kev siv ntau yam, los ntawm cov khoom siv tsheb mus rau cov khoom siv tshuab precision thiab tshaj.Txawm hais tias koj yog cov chaw tsim khoom, tus tsim qauv, lossis tus kws tshaj lij, koj tuaj yeem tso siab rau Steel 5CrNiMo / 5CrNiMoV los muab kev ua haujlwm thiab ua haujlwm ntev uas koj xav tau.. -

Hlau 40Cr

Steel 40Cr yog ib tug nruab nrab carbon siab zog carbon structural steel.Nws lub zog siab thiab hardness ua rau nws muaj kev xaiv nrov hauv ntau qhov kev lag luam, suav nrog kev tsim cov pwm ua haujlwm siab.

Ib lub tuam txhab uas siv Steel 40Cr hauv nws cov txheej txheem pwm yog Kaihua Mould.Nrog rau ntau tshaj 20 xyoo ntawm kev paub hauv pwm tsim thiab tsim, Kaihua Mould tau mob siab rau siv cov ntaub ntawv zoo tshaj plaws thiab thev naus laus zis los tsim cov pwm zoo rau lawv cov neeg siv khoom.

Steel 40Cr yog ib qho zoo meej haum rau Kaihua Mould cov kev xav tau, vim nws tuaj yeem kho tau yooj yim thaum tshav kub kub kom ua tiav qhov xav tau ntawm hardness thiab lub zog.Txawm hais tias nws yog normalizing, quenching thiab tempering, los yog high-frequency nto quenching, Steel 40Cr tuaj yeem raug kho kom tau raws li cov kev cai tshwj xeeb ntawm cov pwm pwm.

Kaihua Mould kev cog lus rau kev siv cov khoom zoo li Steel 40Cr tsuas yog ib txoj hauv kev uas lawv ua kom lawv cov pwm zoo tshaj plaws.Los ntawm kev sib txuas lawv cov kev txawj ntse nrog cov thev naus laus zis tshiab thiab cov ntaub ntawv, Kaihua Mould tseem ua tus thawj coj hauv kev lag luam pwm.