Khoom

-

Kab rov tav Machining chaw

Lub kab rov tav Machining chaw, tsim los ntawm Kaihua pwm, yog kev ua si-hloov pauv ntawm kev kub ceev thiab siab ntxaiv ntxaiv. Kev muab cov nqi tshem tawm tshwj xeeb, lub chaw ua haujlwm no ua tiav cov khoom lag luam zoo thiab zoo ua tau zoo hauv qab cov khoom siv tsim nyog. Nruab nrog kev siv thev naus laus zis, lub kab rov tav machining chaw yog qhov zoo tshaj plaws rau kev lag luam machining kev siv hauv kev lag luam xws li aerospace, tsheb, thiab kho mob. Nrog nws cov txiaj ntsig siab tshaj plaws thiab cov kev ua tau zoo tshaj plaws, lub chaw ua haujlwm no yog qhov kev tsim khoom lag luam nrhiav kom nce cov khoom tsim kho kom zoo ntxiv, txo cov nqi, thiab txhim kho cov khoom lag luam zoo. -

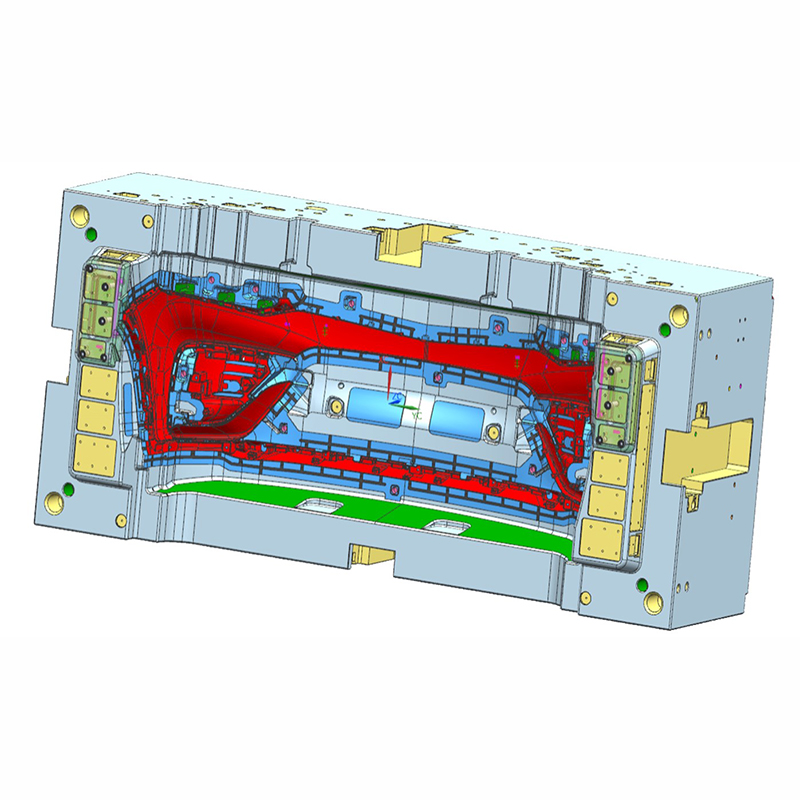

Sab nraud Parting Tsheb Bumper Pwm nrog 42S Luv voj voog

Peb sab nraud cov tsheb bumper pwm nrog 42S lub voj voog luv yog tsim thiab tsim los ntawm Kaihua pwm, ib qho chaw tsim khoom ntawm cov tshuab pwm pwm. Nrog nws cov qauv kev tsim qauv zoo siab thiab cov qauv siv hluav taws xob, peb cov khoom muaj txiaj ntsig zoo rau txhua yam koj siv tau cov kev xav tau lag luam. Peb pab pawg kws tshaj lij yog kev cob qhia kom xa cov kev ua tiav thiab qhov tseeb hauv txhua cov khoom peb tsim. Txij thaum pib ua tiav, peb siv cov ntaub ntawv zoo tshaj plaws thiab cov tswv yim los xyuas kom meej tias koj cov pwm sau kom zoo thiab muaj txiaj ntsig. Xaiv peb cov khoom sib txuas sab nraud ntawm cov tsheb sib txuas thiab kev paub qhov zoo tshaj plaws hauv kev siv tshuab moulding. -

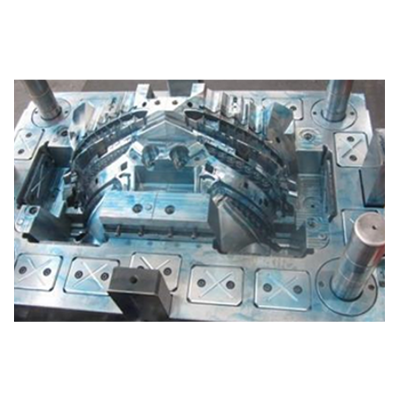

Sab hauv parting tsheb pwm pwm nrog nyias phab ntsa tsim

Kaihua pwm zoo siab muab peb sab hauv lub tsheb pating tsheb pwm moulder nrog lub cim nyias-phab ntsa tsim. Featuring GATEnd lub rooj vag 12 tee thiab kab noj hniav parting thev naus laus zis, lub Automotive Moulding tau ua haujlwm zoo dua thiab zoo rau koj cov kev xav tau ntau lawm. Txawm hais tias koj tab tom nrhiav ib qho txheej txheem ntau dua lossis cov khoom lag luam zoo dua, peb pab pawg ntawm cov kws tshaj lij los pab. Nrog rau kev tsom mus rau kev tshaj lij, precision, thiab kev yooj yim, peb sab hauv lub tsheb bumper pwm yog qhov kev daws teeb meem zoo tshaj plaws rau koj cov kev tsim kho tsheb. Xaiv Kaihua pwm rau txhim khu kev qha, txiav tshuab koj tuaj yeem ntseeg tau. -

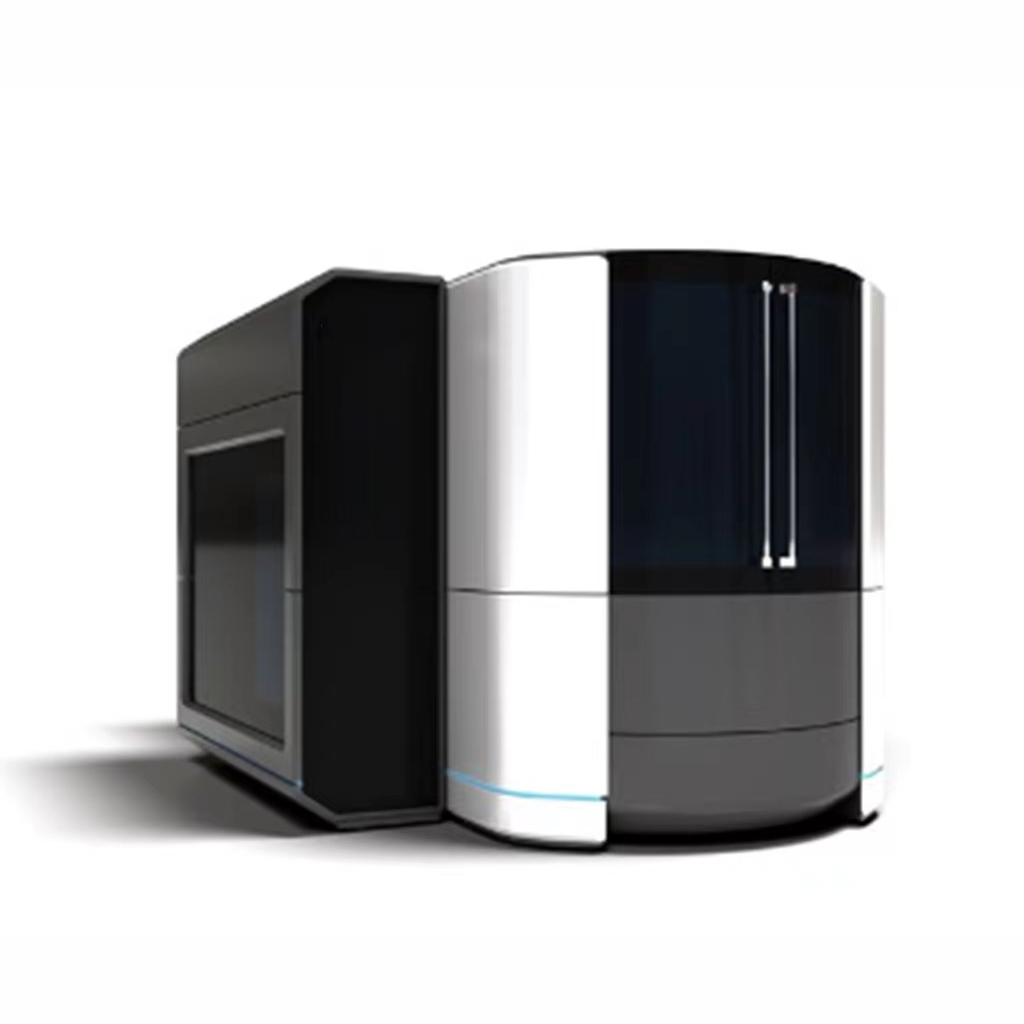

5-axis ntsug machining chaw

Peb 5-axis ntsug machining chaw yog tsim tshwj xeeb rau kev siv cov pwm loj thiab sib sib zog nqus. Nrog rau cov qauv sib cuam, nws tso cai rau kev ua tau zoo los ntawm ib sab. Lub tshuab no yog nruab nrog kev sib hloov ntxiv thiab viav vias thiab kev txwv cov txheej txheem zoo dua thiab tiv thaiv cov peev xwm sib tsoo ntawm lub cuab yeej, shank, thiab kab noj hniav. Tsim los rau qhov ntsuas siab thiab ntau tshaj plaws ua haujlwm, nws yog qhov cuab yeej zoo tshaj plaws rau cov ntawv thov pwm. Peb tau txaus siab pab cov neeg siv khoom zoo li Kaihua pwm, uas peb tau ua lub koob npe nrov rau muab cov khoom lag luam zoo tshaj plaws uas tau ua tiav cov qauv kev lag luam zoo tshaj plaws. -

5-axis kab rov tav tshuab

Lub 5-axis kab rov tav machining chaw yog qhov kev daws teeb meem zoo tshaj rau kev siv tshuab geometric. Ua tsaug rau nws cov kev sib hloov ntxiv thiab viav vias lub peev xwm, lub xeev-ntawm-cov khoom siv-ntawm-cov khoom siv tuaj yeem pab tsim cov txheej txheem zoo thaum machining thiab tawv ncauj. Nrog rau kev ua kom pom tseeb ntawm precision thiab qhov tseeb, lub tshuab no tuaj yeem pab zam kom tsis txhob muaj kev pheej hmoo ntawm cov cuab yeej, sathity phab ntsa puas tsuaj, ua rau kev xaiv zoo tagnrho rau cov tub txawg hauv kev lag luam. Txawm hais tias koj ua haujlwm me me lossis cov txheej txheem loj, 5-axis kab rov tav tshuab los ntawm Kiahua pwm yog qhov kev xaiv zoo tshaj plaws rau cov machining zoo kawg. -

Ntsug Machining Chaw

Kaihua pwm lub chaw ntsug yog qhov kev daws teeb meem zoo tshaj plaws rau ntau yam ntawm cov kev ua lag luam xav tau, los ntawm semiconductors rau cov khoom siv kho mob. Nrog cov vaj huam sib luag ua haujlwm qub thiab cov khoom tswj tau siab heev, lub tshuab no muaj nce cov khoom lag luam nce ntxiv thiab txo tus neeg ua haujlwm nkees. Qhov zoo tagnrho rau kev lag luam xws li aerospace, tsheb, thiab ntau dua, lub chaw ntsug ntsug yog tsim los kom tau raws li cov qauv siab ntawm qhov tseem ceeb ntawm precision thiab zoo. Txawm hais tias koj nyob hauv kev xav tau kev tiv thaiv sai los yog cov khoom siv siab ntau, Kaihua pwm cov tshuab ntsug yog qhov cuab yeej tseem ceeb rau kev ua tiav koj cov hom phiaj tsim. -

Phiaj xwm nyiaj txiag

Peb to taub qhov tseem ceeb ntawm kev ntseeg siab thiab ntseeg tau cov neeg siv khoom sib raug zoo. Tias yog vim li cas peb muab txoj kev npaj nyiaj txiag rau cov neeg uas txaus siab yuav tuaj yeem tuaj yeem pwm, tshuab machinet, thiab cov khoom siv tab sis yuav tsis muaj nyiaj txaus. Peb txoj kev npaj ua kom ntseeg tau tias koj tuaj yeem tau txais cov khoom lag luam zoo uas koj xav tau thaum ua tiav koj li nyiaj txiag. Ntawm Kaihua pwm, peb muaj nuj nqis ncaj ncees thiab siv zog los muab kev pabcuam kev tshaj lij thiab kev ntseeg siab rau peb cov neeg siv khoom. Tiv tauj peb kom paub ntau ntxiv txog peb txoj kev npaj nyiaj txiag thiab peb tuaj yeem pab koj ua tiav koj cov hom phiaj. -

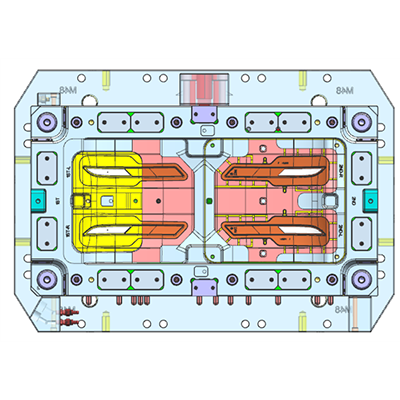

Automotive backup teeb ob-xim 2-ua hauj lwm pwm

Peb lub tuam txhab tshwj xeeb hauv kev tsim lub tshuab kho tsheb lub teeb khawm Pack-xim 2-ua hauj lwm pwm. Nrog Kaihua pwm ua peb tus khub, peb tuaj yeem muab cov tshuaj zoo rau tag nrho koj cov Automotive Pwm xav tau. Peb cov khoom lag luam yog tsim thiab tsim nrog cov kev tshaj lij thiab kev ntseeg siab. Raws li tus kws kho mob yas pwm rau cov teeb lub cev, peb tau cog lus los ntsib cov qauv siab tshaj plaws ntawm qhov zoo. Peb nkag siab txog qhov tseem ceeb ntawm kev muaj lub teeb txhim khu kev qha thiab ruaj khov rov qab, thiab peb cov pwm raug tsim los txhawm rau tsim kom paub tseeb tias koj lub tsheb backup ua raws li cov cai no. Xaiv peb cov khoom lag luam rau kev ntseeg siab, txhim khu kev qha, thiab cov tshuaj zoo rau koj cov Automotive Pwm xav tau. -

Tshuab moulding tshuab

Peb tshwj xeeb hauv kev txhawb nqa tshuab tshuab moulding tshuab, ua rau ntau yam kev lag luam. Peb cov tshuab feem ntau siv hauv cov thawv ntim ntau lawm rau cov tee qhov muag muag, tshuaj, tshuaj pleev ib ce, khoom noj tshuaj, thiab dej paug. Txawm li cas los xij, vim lawv qhov kev ua tau zoo, nqi ua haujlwm zoo, thiab lawv daim ntawv thov tau nthuav dav nrawm rau hauv cov khoom lag luam hauv tsheb. Peb txoj kev koom tes nrog Kaihua pwm muab peb nrog kev txawj ntse thiab thev naus laus zis uas xav tau kom xa cov tshuab moulding zoo uas ua tau raws li koj cov kev xav tau tshwj xeeb. Ntseeg peb los muab kev daws txoj kev ntseeg tau rau koj cov kev xav tau kev tsim khoom. -

Automotive Rearts Los Ntawm TEEB Mould Mould

Peb ntawm Kaihua pwm muab cov khoom lag luam zoo ua ke teeb ci ua ke teeb pwm tuaj, ua rau cov kev xav tau ntawm kev lag luam automotive. Raws li tus kws kho mob yas tshuab, peb paub tseeb tias precision thiab raug nyob rau hauv peb cov khoom, xa tsis muaj dab tsi tab sis qhov zoo tshaj plaws rau peb cov neeg siv khoom. Peb lub teeb taws tsheb pwm tau ua tiav cov khoom siv ua kom zoo, muab lawv lub neej ntev-ntev thiab txo tus nqi kho thiab kho. Nrog peb cov kws tshaj lij hauv cov pwm hauv tsheb, peb ib txwm khaws peb tus kheej nrog cov kev hloov tshiab tshiab thiab cov thev naus laus zis hauv lub tshav pob, muab peb cov neeg tau txais kev daws teeb meem. Xaiv Kaihua pwm rau cov kev pab cuam tsis zoo thiab zoo dua qub. -

Muaj Tsim Txuj

Kaihua pwm tau ua tus kws paub txog kev txhaj tshuaj, ntxig thiab muaj peev xwm txhim kho cov khoom lag luam yas txij li 2000. Nrog rau kev nkag siab zoo ntawm peb cov neeg siv khoom lag luam. Peb cov kev pabcuam tuaj yeem lav cov qauv ncaj ncees thiab kev ua haujlwm los txhim kho lawv cov khoom lag luam 'kev sib tham thiab kev ua haujlwm. Peb cov kws tshaj lij yuav pab peb cov neeg cov khoom lag luam sawv tawm hauv kev sib tw nrog peb cov txheej txheem tsim kev tsim khoom zoo. Ntseeg Kaihua pwm kom coj koj cov khoom mus rau qib tom ntej, thiab cia peb pab koj kom ua tiav qhov siab tshaj plaws. -

Kev Pabcuam

Kaihua pwm yog koj txoj kev mus cuag tshuaj rau kev soj ntsuam cov kev pabcuam cuam tshuam nrog cov khoom siv pwm, cov khoom siv machining, thiab khoom siv thiab khoom siv thiab khoom siv. Peb cov kws tshaj lij ntawm cov kws kho mob zoo muab ntau txoj kev tshuaj xyuas thiab kev pabcuam txais kev lag luam uas cuam tshuam nrog kev lag luam yas thiab kev lag luam yas. Peb txoj kev mob siab rau kev paub thiab prefision kom ntseeg tau tias tag nrho ntawm peb cov kev pabcuam yog qhov ua tau zoo tshaj plaws. Peb zoo siab rau kev xa khoom raug rau peb cov neeg siv khoom, pab lawv xyuas kom meej tias lawv cov khoom ua raws cov qauv zoo tshaj plaws thiab ua raws. Ntseeg Kaihua pwm kom xa cov kev tshuaj ntsuam xyuas koj yuav tsum coj koj txoj kev lag luam mus rau qib tom ntej.